You are here:Home » Product show » Intelligent visual inspection system

Performance features

◎ Friendly operation interface and convenient maintenance and servicing, easy cleaning.

◎ Mold can be replaced simply and rapidly without tools.

◎ DD motor direct drive technology is adopted to achieve stable tracking, without clearance error.

◎ The clamping positioning of product adopts the clamping claw design so that there isn't any ## and blind spot in test. The clamping jaw's clamping force, speed, rotation speed, number of rotation turns and rotation time can be adjusted ##.

◎ Unqualified products can be eliminated by classification for the data analysis and statistics of production status by QA personnel.

◎ With standard configuration + option configuration, test items can be customized flexibly.

◎ Test data and test process are recorded synchronously and the statement can be printed at any time.

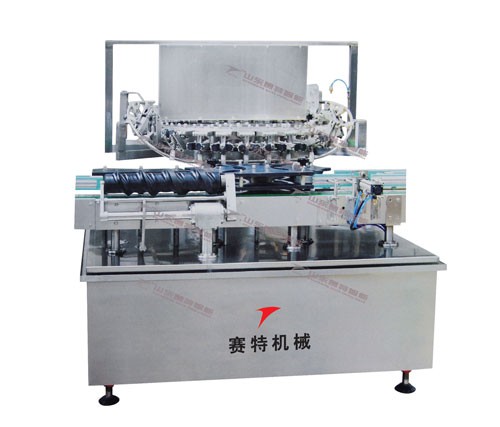

Full-automatic intelligent light inspection machine of white spirit is the automatic online equipment used before the test of foreign matters and appearance of liquid products with transparent packaging in production line of white spirit. It is used to test the glass chippings, rubber crumb, hair, fiber, etc. and the bottle damage, liquid level, bottle cap, etc. and automatically eliminate unqualified products. Compared with the manual test, it greatly improves the test speed and quality and avoids the instability of manual test. It tests the ## of product, and adopts uniform test method and standard to effectively prevent unqualified products from entering the market for circulation. The front end is configured with automatic shake flask and bottle turnover function to achieve the automatic testing of the whole production line.